Technical Specifications | Value |

Operating supply voltage, three-phase | 415 V, 50 Hz |

Mains frequency, Hz | 48-62 |

Rated current of CT, A | 5 |

(Phase/line) voltage hysteresis, V | 10/17 |

Heat hysteresis, in % of accumulated heat in case of shutdown | 33 |

Determination accuracy of trip threshold for current, not more, in % of rated value | 2 |

Determination accuracy of trip threshold for voltage, not more, V | 3 |

Determination accuracy of out-of-phase voltage, not more, V | 3 |

Voltage when maintaining serviceability: – phase voltage, when powered by one phase and zero wire is connected, not less, V – line voltage, when powered by three phases, not more, V | 180 450 |

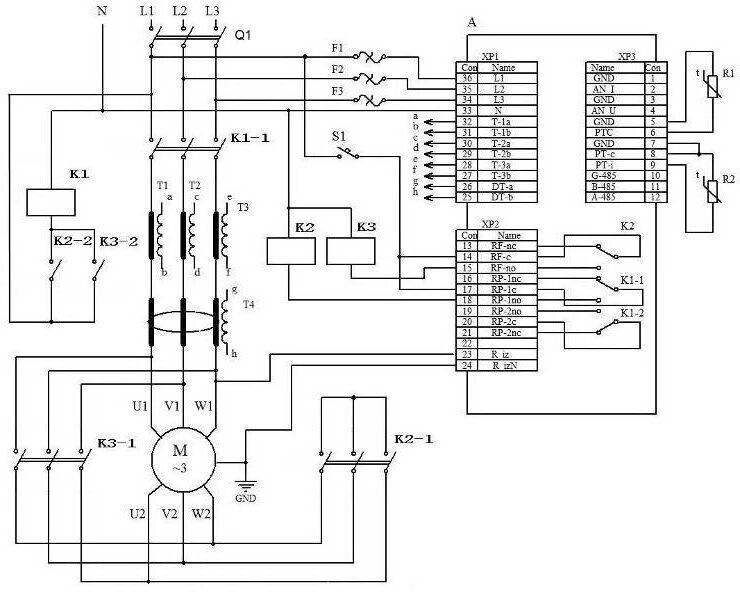

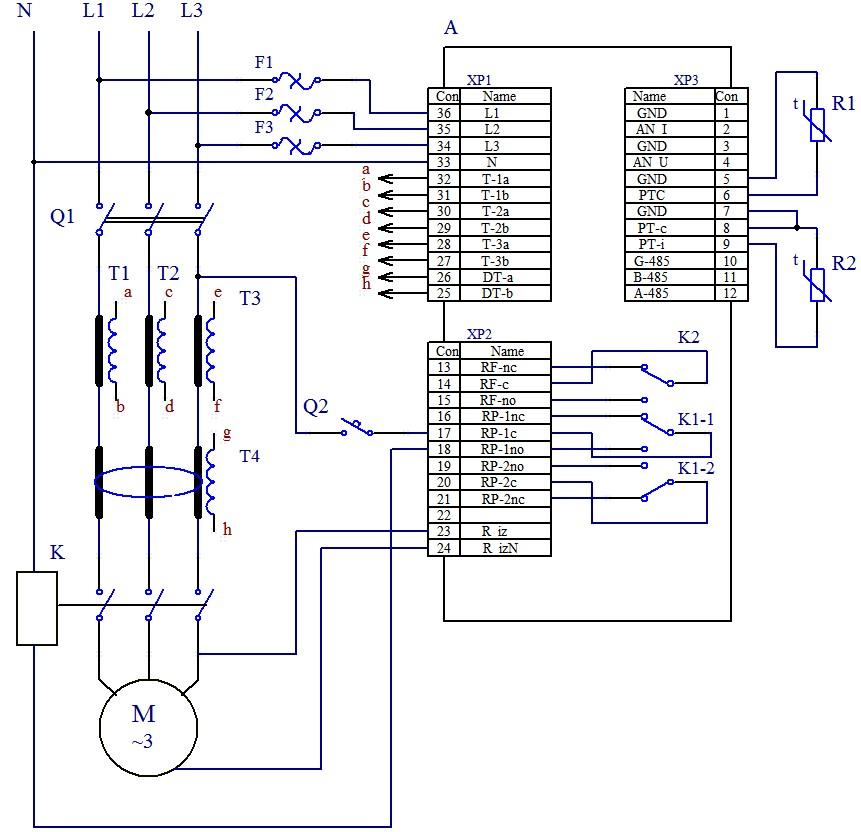

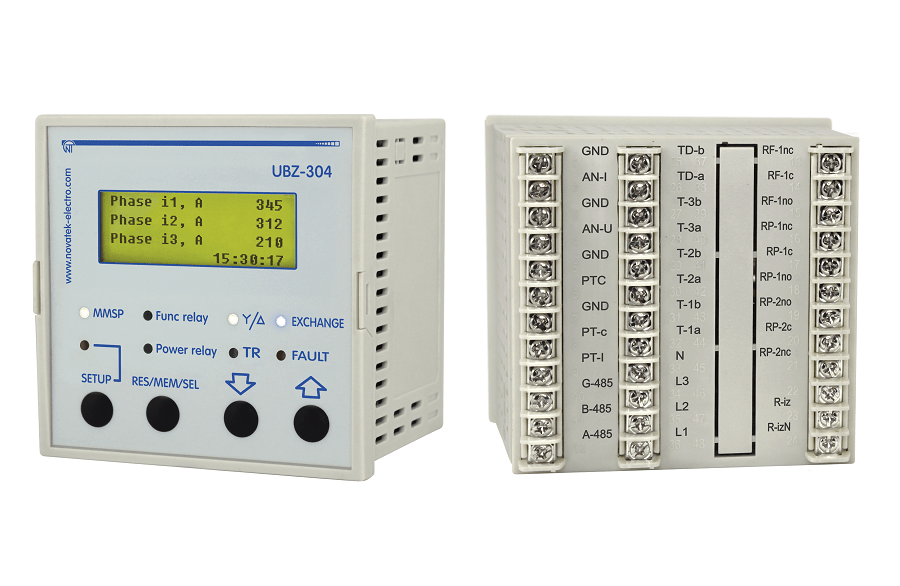

Analog inputs: – input to connect temperature transmitter (types: Pt100, Ni100, Ni120), pc.; – input to connect temperature transmitter of PTC-1000 type, pc.; – three analog inputs for standard CT with 5A output (T-0.66 type or similar), pc.; – input to connect differential current transformer (zero sequence transformer) pc.; – input to measure current of 0-20 mA, pc.; – input to measure voltage of 0–10 V, pc.. | 1 1 3 1 1 1 |

Main outputs: – load relay – two groups of changeover contacts to control the electric motor starter – 8 A, 250 V at cos φ=1; – functional relay – one group of changeover contacts – 16A, 250V at cos φ=1 (function of the relay is set by the user). | |

Permit according to temperature of temperature transmitters, °С | 1 |

Power consumption (under load), VA, not more | 5.0 |

Weight, not more, kg | 0.34 |

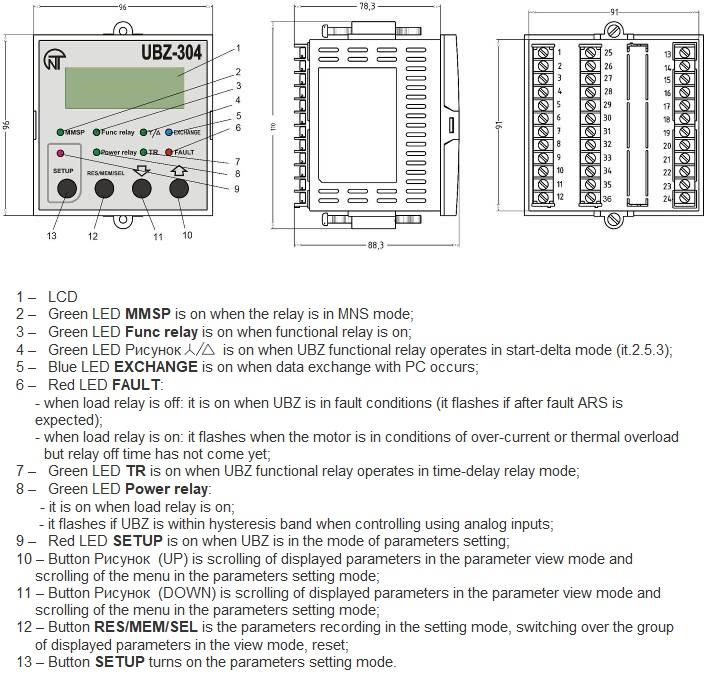

Overall dimensions (Fig.1.1), H*B*L, mm 110*96*88,3 Position in space free Housing material self-extinguishing plastic |